CASE STUDY

Nu-Age Plaster save money with a second hand dust collector customised with new ducting and dust extraction hoods

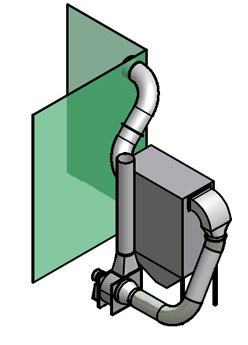

Nu-Age Plaster wanted to improve working conditions in their manufacturing plant, but cost was an issue. DUSTEX found an ideal second-hand dust collector, and manufactured new ducting and dust extraction hoods to suit.

Background:

Nu-Age Plaster was keen to improve working conditions for staff working in their manufacturing plant.

The problem:

At the time, everyone in the building industry was being hit by a recession. Therefore Nu-Age Plaster was conscious, more than ever, of spending wisely.

The solution:

DUSTEX managed to find Nu-Age Plaster a second-hand dust collector in good condition that met their requirements precisely. New ducting and dust extraction hoods were manufactured to complete the system.

Nu-Age Plaster wanted to improve working conditions in their manufacturing plant in a cost-effective way. DUSTEX sourced a second-hand dust collector, and manufactured new ducting and dust extraction hoods to suit.